Recommended Grades

Grades selected for floor and wall tile production, balancing fired whiteness, mechanical strength, and dimensional stability at scale.

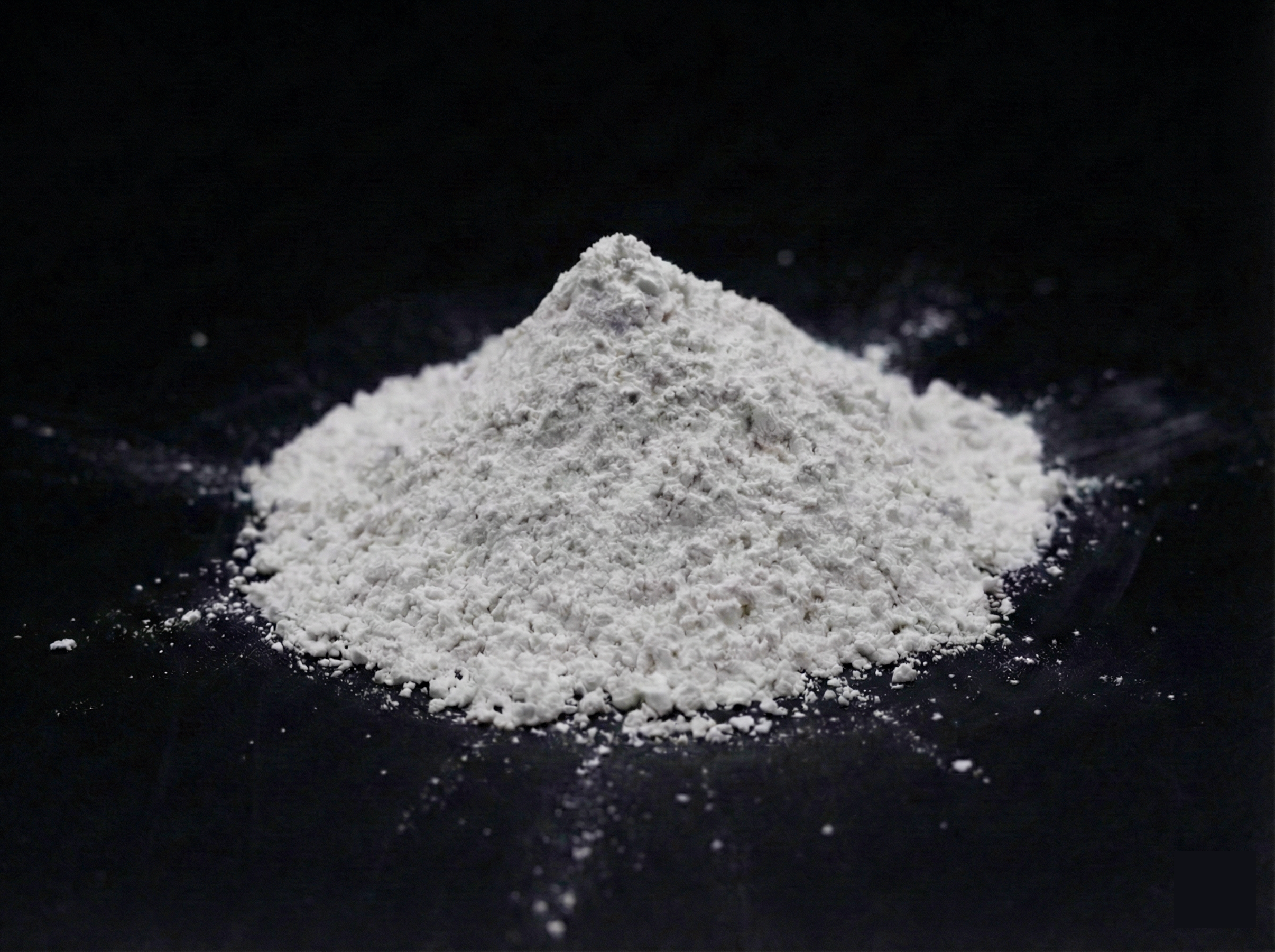

UT-WHITE

A high-volume tile body kaolin providing the plasticity needed for consistent pressing and extrusion. Its controlled shrinkage and reliable mineralogy produce dimensionally stable tiles with clean, bright fired surfaces.

UT-WASH

A washed, grit-free grade for premium glazed and polished tiles. Higher alumina content supports a stronger tile body, reducing warpage and improving resistance to crazing in the glaze layer.

UT-ULTRA

Our upcoming calcined grade engineered to maximise opacity and surface brightness in the tile glaze layer itself. Ideal for ultra-white, high-gloss large-format tiles where visual uniformity is critical.