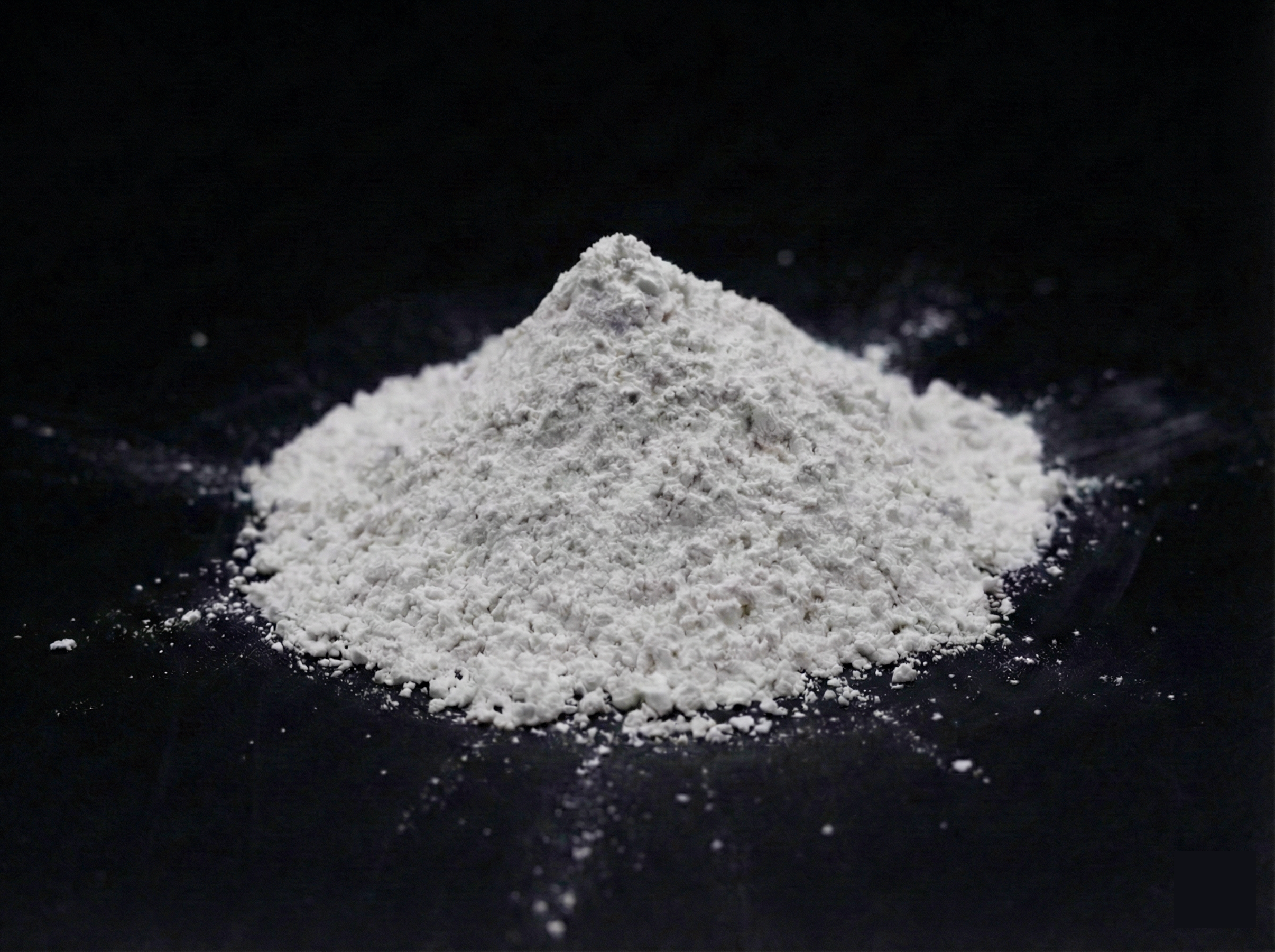

Recommended Grades

Selected grades tailored for ceramic applications, from sanitaryware and tableware to technical refractories.

UT-WHITE

A versatile ceramic body kaolin offering excellent plasticity and green strength. Ideal for sanitaryware, tableware, and general-purpose ceramic forming where workability and consistent shrinkage are key.

UT-WASH

A meticulously washed grade with higher Al2O3 content for superior fired strength. Grit-free purity ensures defect-free surfaces in premium porcelain, bone china, and high-specification sanitaryware.

UT-ULTRA

Our upcoming premium calcined kaolin fired at high temperatures to maximise opacity and structural hardness. Engineered for advanced technical ceramics and specialty refractory applications requiring near-zero impurities.