Recommended Grades

Grades for adhesive and sealant formulations — controlling rheology, reducing cost, and improving thermal and moisture resistance.

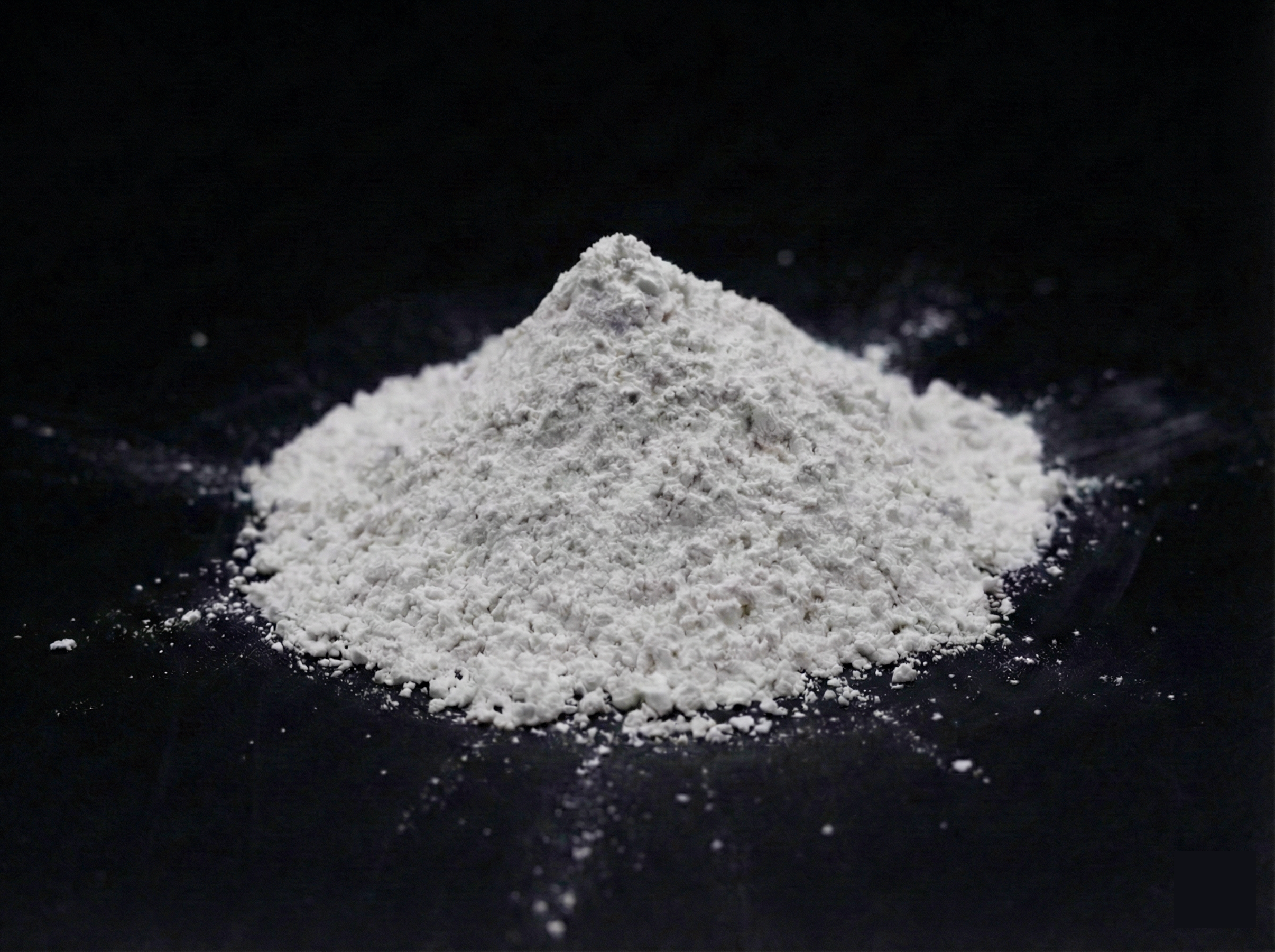

UT-WHITE

A functional extender for water-based adhesives and construction sealants. Its platelet morphology acts as a rheology modifier, improving sag resistance in vertical applications and reducing overall formulation cost without compromising bond strength.

UT-WASH

A fine, washed grade for high-performance adhesives where low grit and consistent particle size are critical. Used in structural epoxies and pressure-sensitive adhesives to improve tack, cohesive strength, and resistance to humidity.

UT-ULTRA

Our upcoming calcined grade for specialty industrial adhesives and thermal-interface materials. High surface area and near-zero metallic impurities improve thermal conductivity and ensure compatibility with sensitive electronic substrates.